image credit: bolton.ac.uk.

Biomedical Engineering: Since the existence of man, they have used materials provided to them by nature to fix, repair or heal their sick ones or any damaged part of the body caused by an impact, an accident, or disease.

Ancient Egyptian mummies used to have artificial eyes, ears, and noses implanted in them. Chinese used to fix body malformation with taxes, glue, and fabric. Due to the advancement in technology and scientific progress, it became possible to develop and create perfect materials, from rudimental orthopedic implants to well-advanced lab-make biomimetic material. These increased the efficiency of Tissue Engineering therapeutic which is part of biomedical engineering.

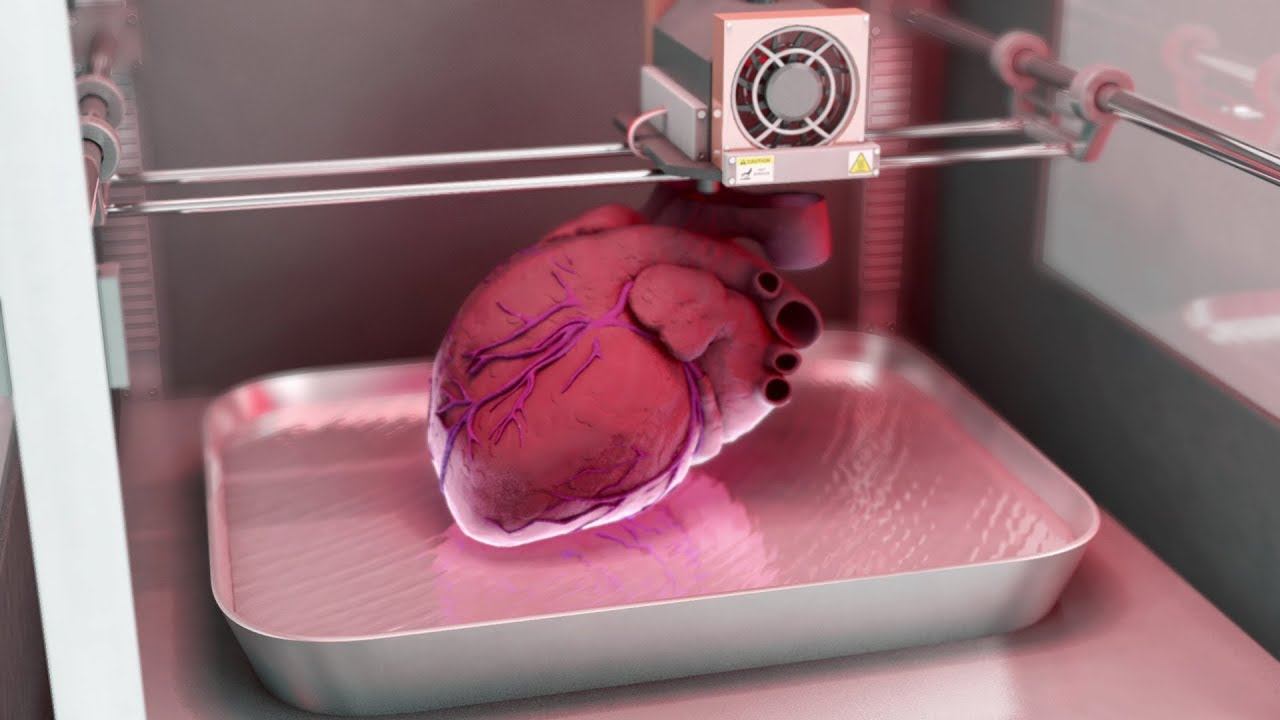

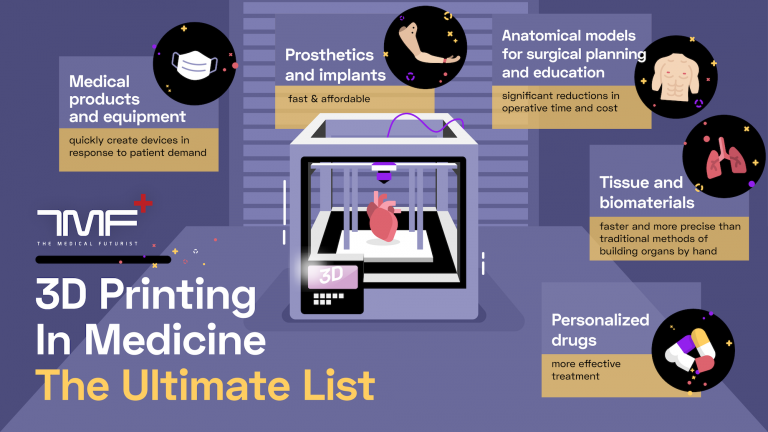

3D printing is among the recent technologies in the medical field. Biomedical 3D printing of prosthetics and biomaterials is being utilized for several medical specialties.

What is 3d printing in biomedical engineering

Let’s start by saying that 3D printing is more of a technology based on sci-fi concepts. With 3D printing, it is possible to create anatomical structures that are very compatible with the human body. The good thing about those structures created through 3D printing is that they can integrate with the body though this depends on the type of material that the anatomical structures are created from.

The 3D-printed prosthetics and implants are only adopted to suit a single determined organism.

The ability to create anatomical structures that are personalized can decrease the rejection and infection rate.

YOU CAN ALSO READ: MEDICAL ROBOTS: EVERYTHING YOU NEED TO KNOW ABOUT MEDICAL ROBOTS

Biomedical Engineering 3D Printing Applications.

Nowadays, the use of 3D-printed products is gradually becoming a norm. There is a vast area in which 3D printing can be used, for instance, in biomedical engineering 3D printing can be used in Orthopedic, Cardiac, Neuro, and also in maxillofacial surgeries.

3D printing can be used in tissue engineering and the indirect development and creation of medical devices.

Recently, some scientists from the University of Tel Aviv succeeded in creating an artificial heart using 3D printing. The artificial heart was printed off from biological materials. This organ has the same weight as a rat or rabbit here, however, it doesn’t pump blood on its own.

Even though the heart created does not pump blood on its own, so many scientists are still working tirelessly and if they succeed in printing a heart that pumps blood, soon we will be facing a revolution in the medical field.

In the near future 3D printing can ease the shortage of organ donors which will lead to a decrease in cost.

Benefits of 3d printing in engineering.

3D printing offers several benefits to both patients and medical personnel. Below are the advantages of biomedical engineering 3D printing.

1. 3D printing offers a more Flexible Design

With 3D printing, medical specialists can create more complex and flexible designed implants than traditional manufacturing processing.

2. 3D printing offers rapid prototyping. Biomedical engineering 3D printing can create parts within some time. Less time is required to manufacture parts when compared to the traditional parts manufacturing process.

3#. Another good advantage that this 3D printing offers is the print-on-demand features. Large space is not required to stock inventory, unlike the traditional manufacturing processes. This print-on-demand will save cost and space as there is no need to print parts that are not needed.

4. Materials used are strong and lightweight: the main material used in 3D printing is plastic, although sometimes metals can be used though this is on special demand. Plastic material covers several advantages over metal equivalents as they are lighter in nature.

5#. 3D printing offers Fast Design and Production. 3D printing can print parts within hours of demand, which is faster than the traditional manufacturing process. The design process is also quick and fast and comes better than the molded or machined part.

Read more: In-Depth Benefits Of Autonomous Mobile Robots For humans And Society At large.

Biomedical 3d Printing companies

These are the companies that specialize in manufacturing and printing technology for medical use and purposes.

They produce the 3d human organs and parts that can be used by medical professionals to provide solutions to humanity.

These companies implement technology to provide perfect solutions to human health.

Examples of biomedical 3d Printing companies

Organology

These are those companies that specialize in combining technology to produce 3d human parts for the betterment of humanity.

Read more: Best Universities for The Study Of Biomedical Robotics Science in Australia

Disadvantages of Biomedical 3d Printing

Some risks may be associated with 3d Printing.

Let’s consider and talk about it so that you will be aware of it.

- Materials: if the materials used are not biocompatible it may cause more harm to human health resulting in more health challenges.

- Maintenance: The cost of maintaining biomedical 3d Printing may be so high bringing more expenses to the user.

To avoid any further harm and disadvantages it will be better if there is an available regulatory body in charge of regulating those biomedical 3d Printing companies.

Read more: Medical Robots: Everything You Need To Know About Medical Robots AndHow It Works.

3d Printing Play Health Risks

Even as beneficial as this biomedical engineering 3D printing may be, it still comes with potential hazards. 3D health risks may include inhaling harmful chemicals or solvents, skin can be exposed to harmful chemicals, and exposure of the body to high temperatures.

3D printing has been linked to cardiovascular disease, Respiratory infection, lung cancer, and even chronic obstructive pulmonary disease (COPD).

The damaging health effects of 3D printing include Central nervous system damage, nasal passage, Irritation of the throat, loss of general coordination, severe headache, skin irritation.

YOU CAN ALSO READ : GIS: OPTIMIZATION OF THE TELECOM INDUSTRY WITH GIS

How To Protect Workers from 3D Printing Health Risk.

Recently, the National Institute for Occupational Safety and Health (NIOSH) has given out guidelines that will help organizations to protect their staff from the potential risk of 3D printing while using 3D printing equipment.

1. Only trained professionals or Staff should be permitted to Operate 3D printing Machines and Equipment.

2. Ensure that 3D printing equipment is placed on its proper location.

3. Organizations should make use of 3D printing machines and equipment with lesser emissions as this will increase the safety of the workers.

4. Only purchase 3D printing equipment that meets the ANSI/CAN/UL 2904 Compliance standards.

5. Ensure that the total time the workers spend on 3D printing equipment is limited.

infographic credit: medicalfuturist

Biomedical engineering minimum requirements.

If you have a dream of becoming a biomedical engineer here are the admission requirements for the biomedical Engineering Master’s program.

- A completed online or offline alongside the application fee.

- A well-written statement of purpose

- Three letters of recommendation from people in academia.

- A bachelor’s degree from an accredited University.

- A minimum grade point of 3.0

- Good GER or GMAT scores.

Biomedical engineering companies in Ireland.

There are a lot of biomedical engineering companies in Ireland. Ireland is actually a good place to study biomedical engineering. And if you are aspiring to be a biomedical engineer consider schooling at any Ireland university.

Here are a few names of Biomedical engineering companies in Ireland.

Ireland is one Country that is in the front of 3D printing equipment development. Even though the country is not known to be all that techy but yet still, they are great when it comes to medical facilities.

As stated earlier, Ireland can boast of many biomedical engineering companies that are in full operation.

YOU CAN ALSO READ: IN-DEPTH BENEFITS OF AUTONOMOUS MOBILE ROBOTS

CONCLUSION

Biomedical engineering 3D printing is the act of creating anatomical structures using improved equipment and method which produces good parts than the traditional manufacturing process that involves molding or machining of the parts.